Introduction

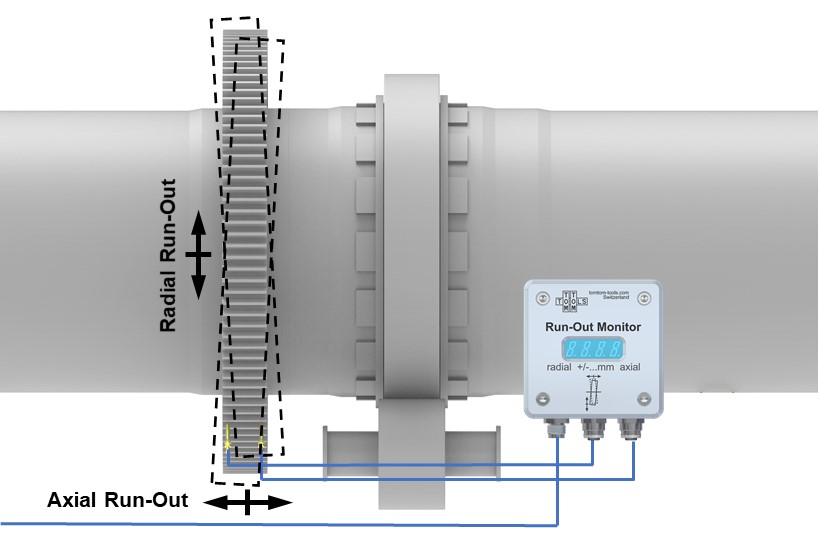

The Run-Out Monitor is designed for two main purposes:

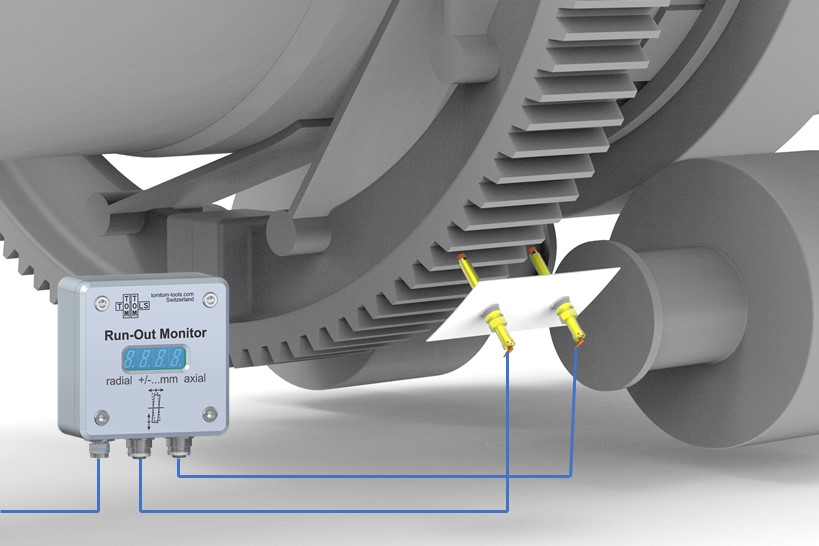

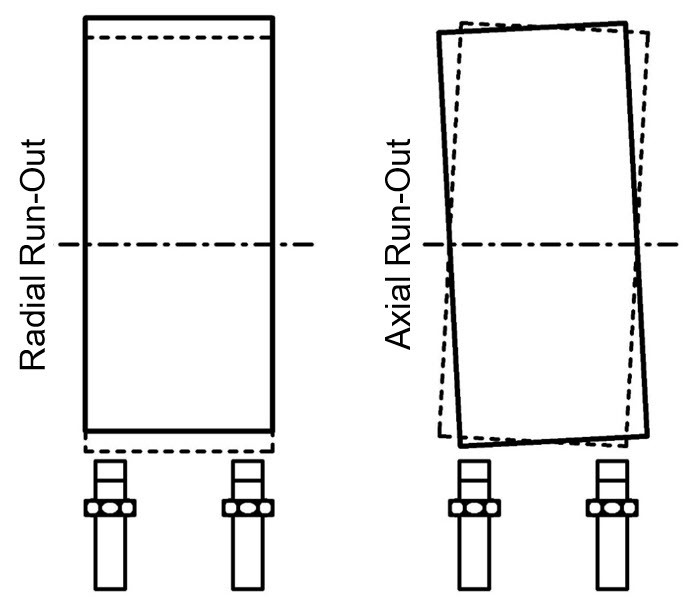

- To monitor the run-out of ring gears

- The run-out of running tracks for slide bearings.

This system measures and warns about dangerous run-out in rotary kilns, tube mills, and rotary dryers and can be used on various other machines with rotating gears prone to run-out.

The alignment of the girth gear and the bearing surfaces are affected by changes in the tubular kiln or ball mill shell.

Uneven temperatures or looseness can result in distortions and affect the girth gear and the bearing surfaces.

Misalignment or run-out of the gear affects the mesh with the pinion, which can cause vibration and damage to the drive train.

Run-out on bearing surfaces (tires, trunnions) is dangerous for the bearings. It can be caused by thermal effects too, but also by cracks.

It is important to detect issues in an early stage to avoid major damage and long downtime.

The Run-Out Monitor is designed to be installed permanently.

It continuously measures the axial and radial run-out and provides the values to the control system of the factory.

Uneven temperatures or looseness can result in distortions and affect the girth gear and the bearing surfaces.

Misalignment or run-out of the gear affects the mesh with the pinion, which can cause vibration and damage to the drive train.

Run-out on bearing surfaces (tires, trunnions) is dangerous for the bearings. It can be caused by thermal effects too, but also by cracks.

It is important to detect issues in an early stage to avoid major damage and long downtime.

The Run-Out Monitor is designed to be installed permanently.

It continuously measures the axial and radial run-out and provides the values to the control system of the factory.