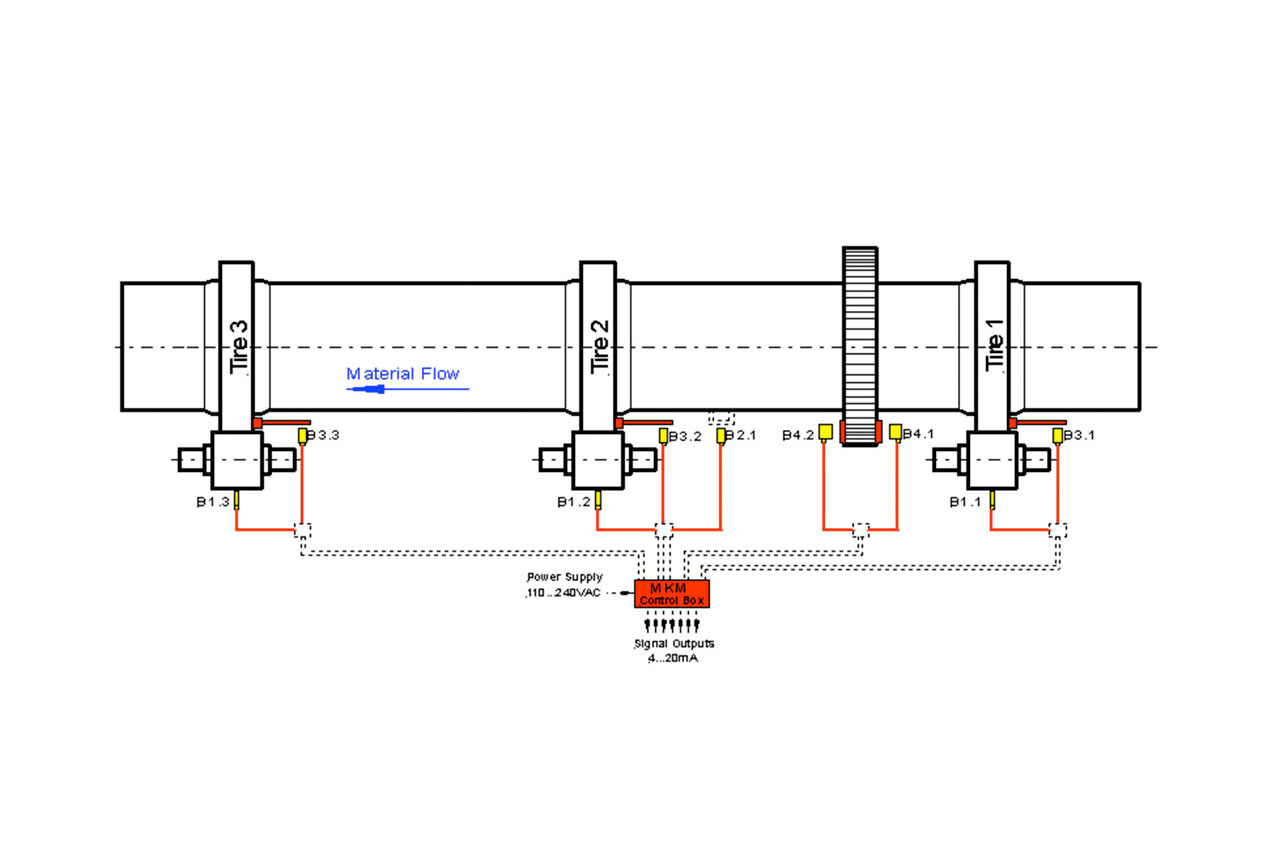

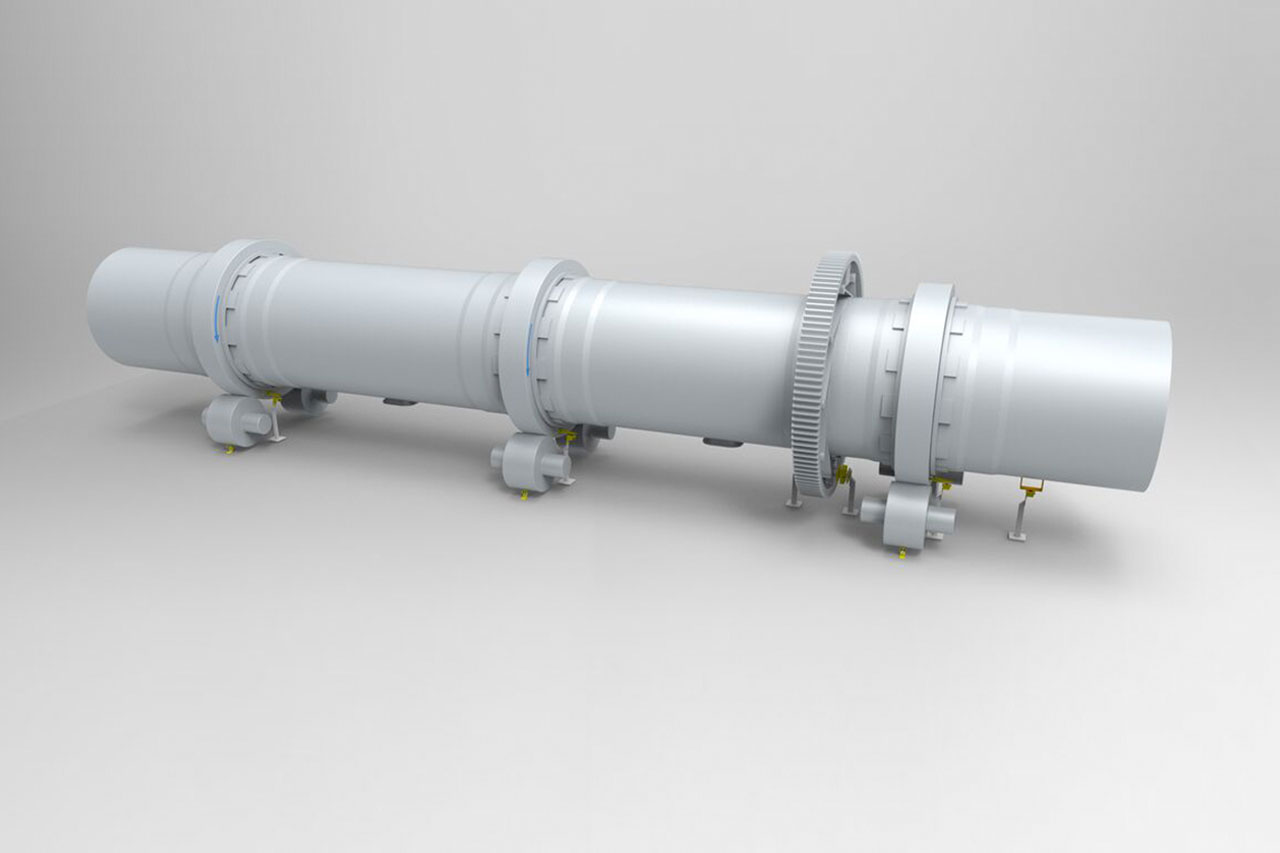

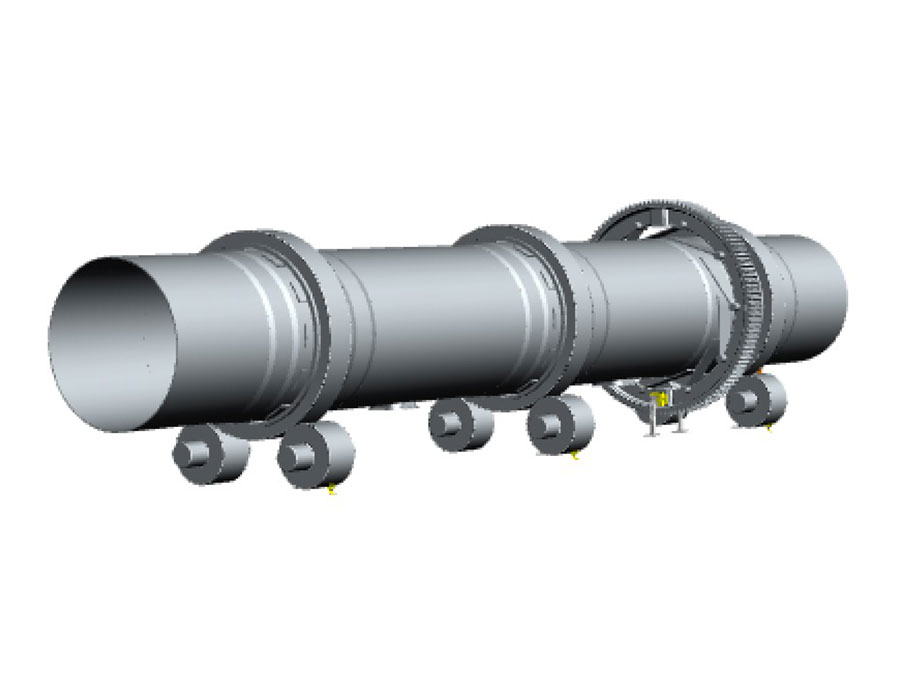

The MKM-System is an on-line measuring unit to detect abnormalities during kiln operation which can lead to mechanical failures on any rotary kiln system (with more than 2 Stations). The main objective is to detect such abnormalities (thermal or permanent kiln cranks, lack of tire play) at an early stage. Analog signal exchange (4 – 20 mA) allows the plant to connect directly with the plant control system to set alarm levels and to take adequate counter-measures.  Furthermore the equipment is storing the measured data to a memory card in a way to perform off-line analysis at any stage to verify the origin of upset condition (process or mechanical).

Privacy Overview

This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.