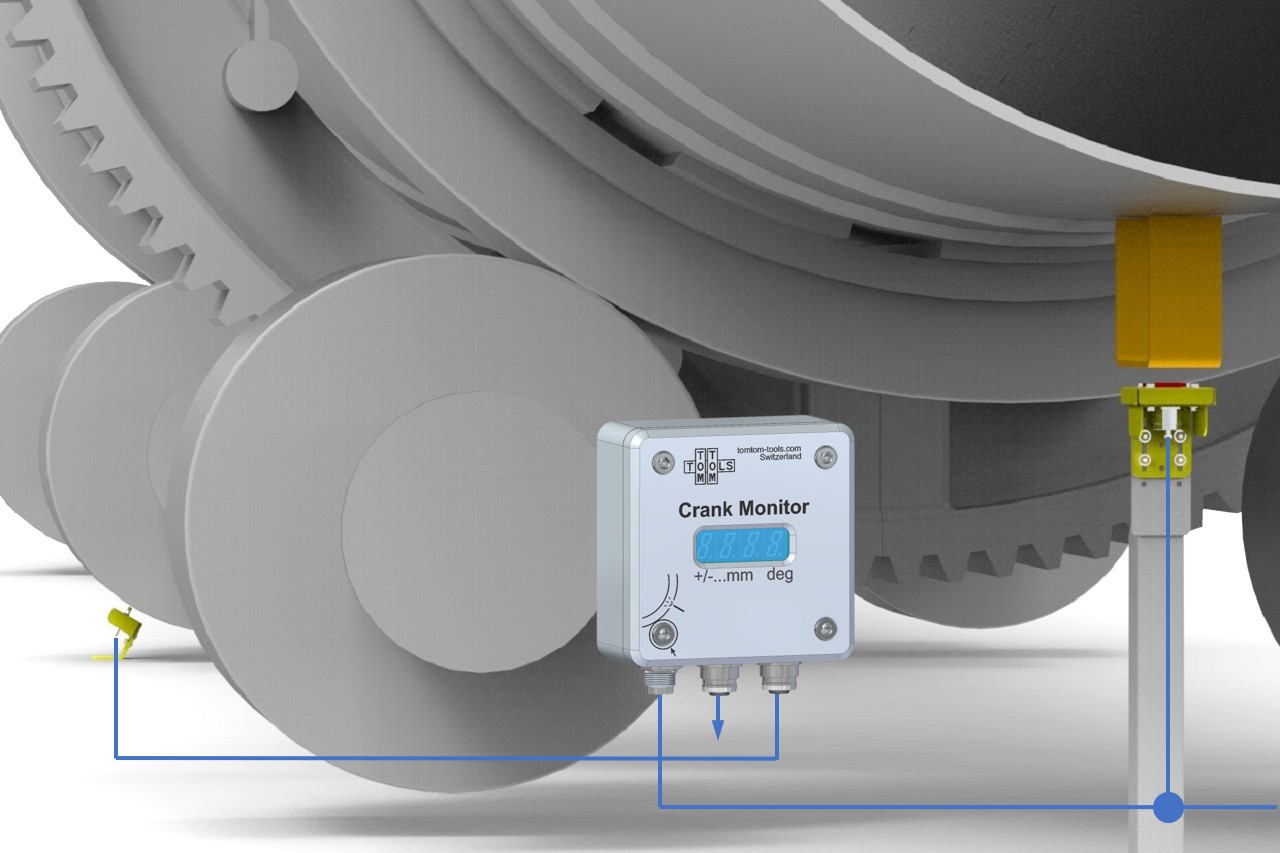

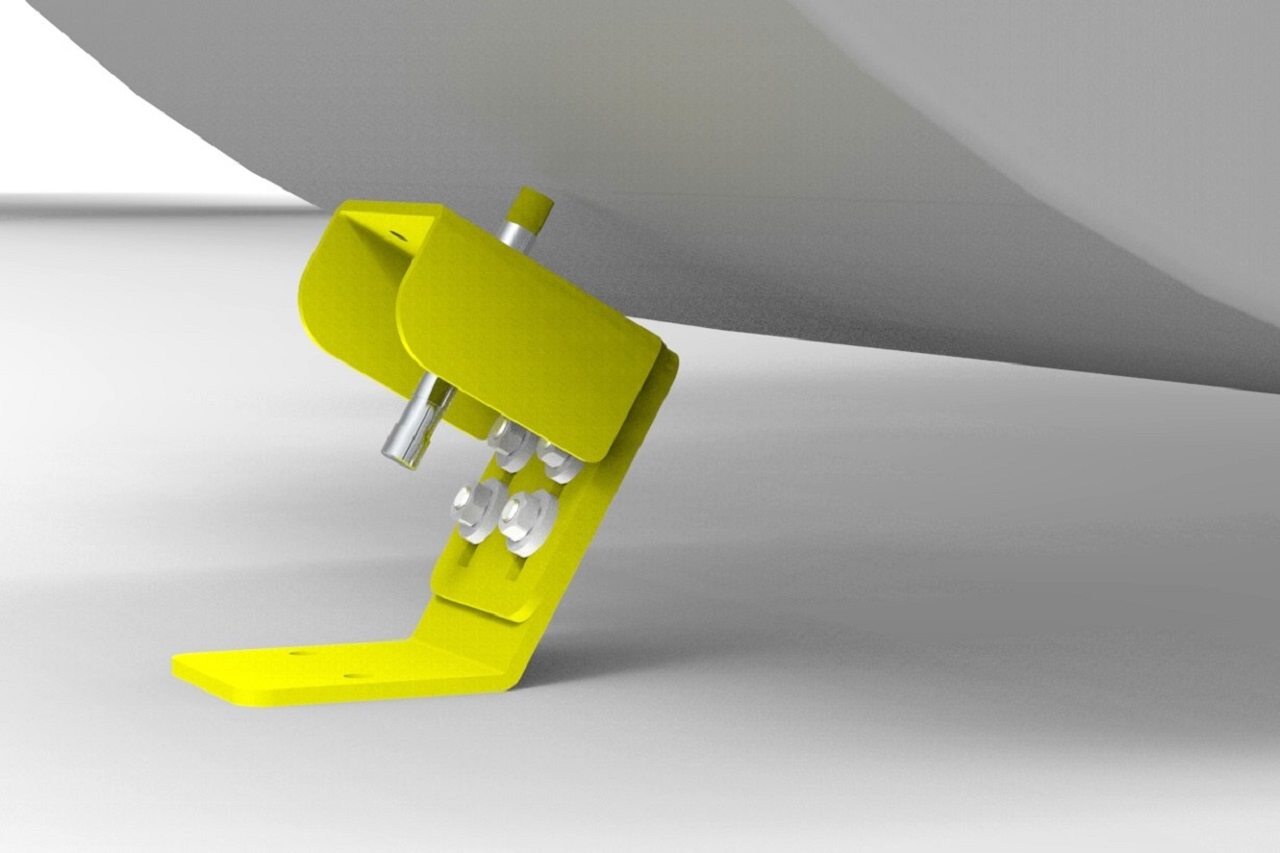

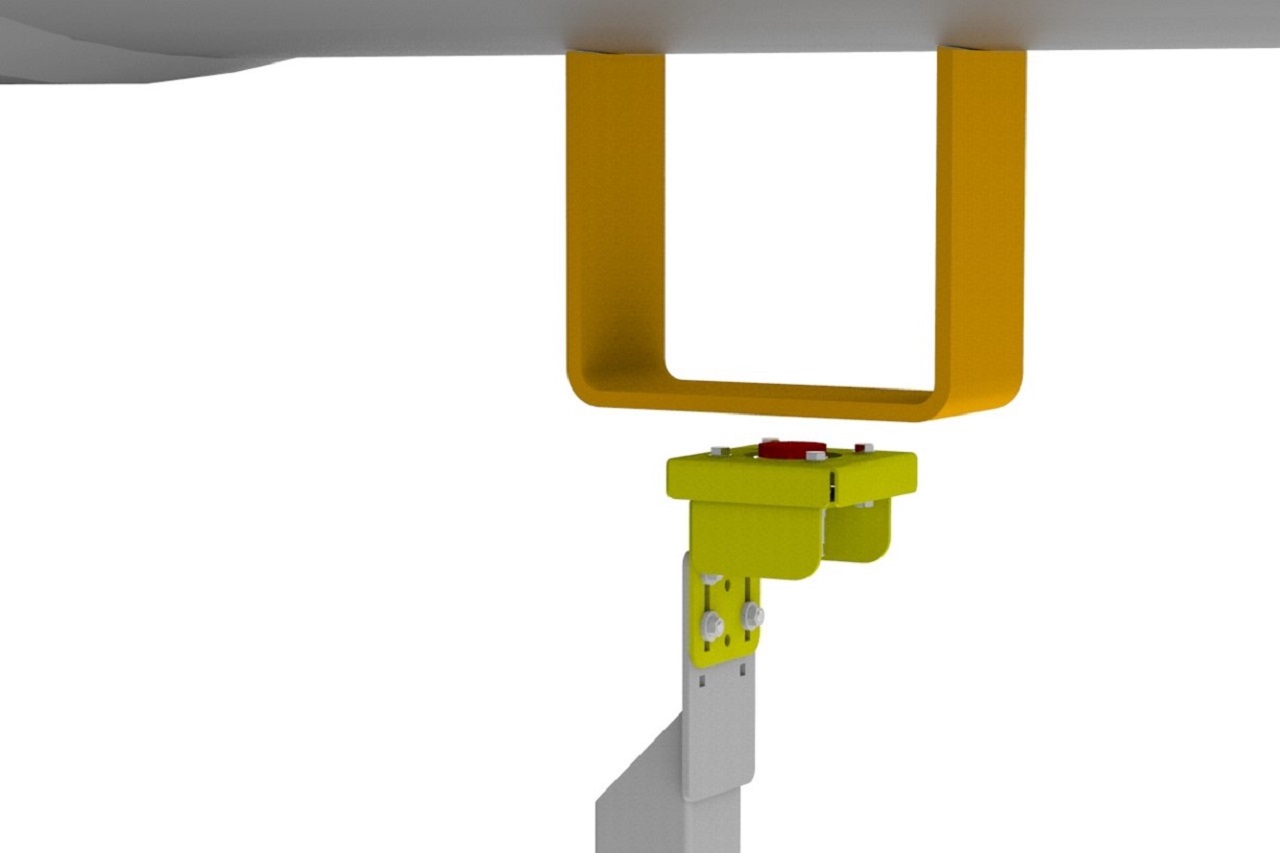

The Crank Monitor is part of the new MKM System 2 and is used to measure and warn about cranks in the kiln. It even can be used as controller for the patented Crank Elimination System which can neutralize cranks by selective shell cooling. More information about counteracting cranks is available separately.

A crank is a deviation in the straightness of the kiln shell, which causes cyclic changes of the support load in the piers. Cranks can cause extreme overload and major damage. They are the main cause for cracks in tires, breakages of roller shafts and sinking foundation.

The Crank Monitor is designed to be installed permanently on kilns with more than 2 piers.